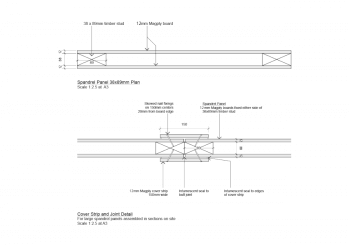

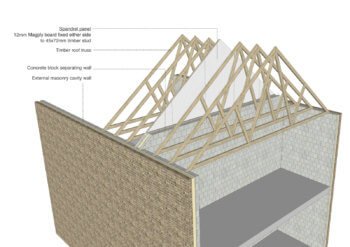

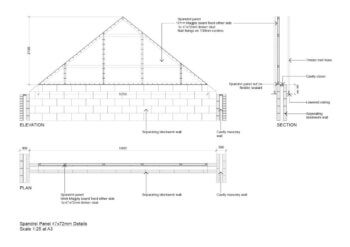

12mm Magply provides a fire-safe, lightweight environmentally friendly solution for Spandrel Panels. As a high performance, multi-functional board, Magply features a Magnesium Sulphate formulation and is manufactured from a production process that ensures a very low chloride content enhancing both stability and durability. Magply is tested for use in spandrel panel applications utilising 12mm board on each side of an uninsulated spandrel frame to BS 476 (Part 22)1987.

Gallery

Magply testing for spandrel panels

BS 476 (PART 22 SPANDREL PANEL) 1987

12mm Magply satisfies the performance requirements specified in BS 476 (Part 22 Spandrel Panel) 1987

Test Results: BS476 (Part 22)

Fire Integrity: 132 minutes

Insulation Integrity: 61 minutes

BS 594 (Racking ReSistance)

Magply has been tested to BS 594 to provide the following Racking Strength

| Nailing Centres | Load per Stud | Racking Resistance to BS 594 |

|---|---|---|

| 150mm/300mm | 0kN | 1.74 kN/m |

| 150mm/300mm | 5kN | 1.70 kN/m |

| 50mm/150mm | 0kN | 5.90 kN/m |

Magply is suitable for outside weather exposure for a minimum of 3 months

Fixing and cutting

Magply not only cuts better, but the boards are not prone to cracking or splitting if they are installed with pressurised nail guns. Magply can be easily cut to size on site using the score and snap method. Using a pencil, mark the required size and score along the pencil line suing a utility knife and straight edge ensuring you cut through the reinforcing mesh.

Magply not only cuts better, but the boards are not prone to cracking or splitting if they are installed with pressurised nail guns. Magply can be easily cut to size on site using the score and snap method. Using a pencil, mark the required size and score along the pencil line suing a utility knife and straight edge ensuring you cut through the reinforcing mesh.