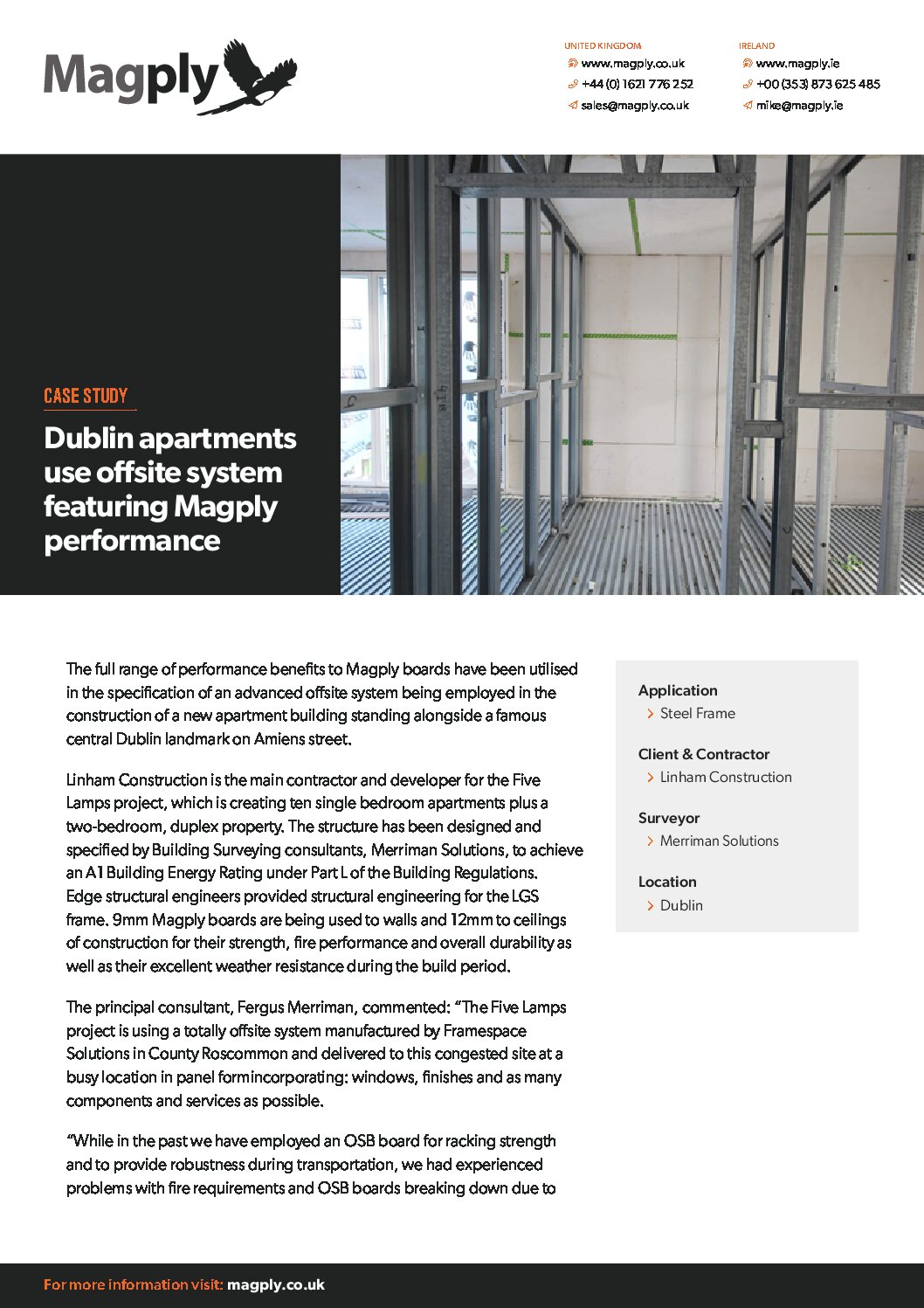

The full range of performance benefits to Magply boards have been utilised in the specification of an advanced offsite system being employed in the construction of a new apartment building standing alongside a famous central Dublin landmark on Amiens street.

Linham Construction is the main contractor and developer for the Five Lamps project, which is creating ten single bedroom apartments plus a two-bedroom, duplex property. The structure has been designed and specified by Building Surveying consultants, Merriman Solutions, to achieve an A1 Building Energy Rating under Part L of the Building Regulations. Edge structural engineers provided structural engineering for the LGS frame. 9mm Magply boards are being used to walls and 12mm to ceilings of construction for their strength, fire performance and overall durability as well as their excellent weather resistance during the build period.

The principal consultant, Fergus Merriman, commented: “The Five Lamps project is using a totally offsite system manufactured by Framespace Solutions in County Roscommon and delivered to this congested site at a busy location in panel form incorporating: windows, finishes and as many components and services as possible.

“While in the past we have employed an OSB board for racking strength and to provide robustness during transportation, we had experienced problems with fire requirements and OSB boards breaking down due to exposure to the weather – and we tend to get a lot of rain in Ireland. That is why we have switched to using the Magply MOS board because they are so stable in all conditions and unlike the OSB do not need to be fire protected separately, the MOS boards provide 1 hour fire protection to structure in their own right so a services zone behind a normal plasterboard lining then provides full compliance with Building Regulations parts B and E. This also means the services installation can commence as soon as walls are erected and the entire construction is now of non combustible materials, a must given recent tragic events”.

The five storey building is being clad across different elevations with either the Permarock exterior wall insulation system or the Dutch manufactured Brickworld brick slip system. Both are on Rockwool material fixed to an outside layer of 9mm Magply sheathing which also provides an additional 1 hour fire protection to the structure from the outside. This solution for the envelope will not only achieve a U-value of 0-15 W/m2 K, but the inherent airtightness of Magply is also helping the project team target an air permeability figure of less than 2.0 m3 /m2 /hour.

Fergus Merriman added: “As well as the 9mm Magply fixed to the outside face of the light gauge metal frames for the external walls, 12mm boards are used on the underside of the floor cassettes above a service zone within each of the flats removing cabling without any need for penetrations to the structural envelope. Overall the Magply is easy to cut and fix, while as an MOS product it can get wet as many times as you want. That helps with programme timing while the price-point also makes it very affordable compared to other fire safe products.

As a high performance, multi-functional board, Magply features a Magnesium Sulphate formulation with no VOC’s to offer a fire-safe and environmentally friendly alternative to conventional plywood or OSB products. Additionally, the unique production process keeps the chloride content to just 0.01%, enhancing both stability, long-term durability as tested by Bunch and avoiding the chloride issues seen with other formulations. Crucially, Magply carries a full suite of internationally recognised accreditations confirming the boards’ ability to deliver up to 90 minutes’ fire integrity and insulation under test conditions and including EN 1365# tests carried out by Exova.

Furthermore, the range offers excellent racking strength, impact and pull-out resistance.

The all round fitness of use is ideal for a wide variety of applications, including panelised and modular systems. Magply has been tested under BS EN 476 Part 22 for timber frame applications and parts 6&7 to provide Class A1 certification for the surface spread of flames together with other approvals such as EN ISO 1182-2010.