Magply Tilebacker is a mineral based, homogeneous, environmentally friendly product with a manufacturing process that produces very little in the way of C02 emissions, unlike cement particle and gypsum boards which both generate high levels of C02. Magply Tilebacker Boards help to provide a safe and healthy living environment whilst being a great surface to tile onto.

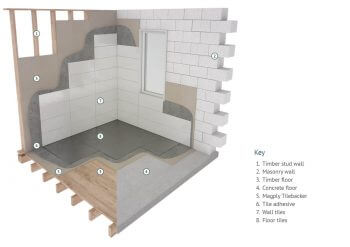

Magply Tilebacker is available in 6mm and 12mm, board sizes are 1200mm x 800mm. The boards are easy to use and the performance and structure are unaffected by moisture, thus Magply Boards can be used in both indoor and outdoor applications including damp locations such as shower areas, bathrooms and wet rooms. Magply Tilebacker can also be formed to follow gentle curves and is very stable and does not expand or contract when subject to temperature changes.

Gallery

Magply testing for Tilebacker

BS EN 1365-1:2012 (Loaded Wall)

Magply has been tested to determine the fire resistance in a Loaded Wall Assembly in accordance with BS EN 1365-1 :2012.

Test Results: BS EN 1365-1:2012

Integrity: 67 minutes

Insulation: 67 minutes

BS EN 1364-1:2015 (PIR Timber Frame)

Magply has been tested to determine the fire resistance in a non-loadbearing, partition wall assembly in accordance with BS EN 1364-1 :2015.

Test Results: BS EN 1364-1:2015 (PIR TIMBER FRAME)

Integrity: 75 minutes

Insulation: 66 minutes

BS 594 (Racking ReSistance)

Magply has been tested to BS 594 to provide the following Racking Strength

| Nailing Centres | Load per Stud | Racking Resistance to BS 594 |

|---|---|---|

| 150mm/300mm | 0kN | 1.74 kN/m |

| 150mm/300mm | 5kN | 1.70 kN/m |

| 50mm/150mm | 0kN | 5.90 kN/m |

Magply is suitable for outside weather exposure for a minimum of 3 months

Fixing and cutting

Score-and-snap the board firmly using a straight edge as a guide. Pull the board edge upwards to snap. Straight cuts: Magply is easily cut using a carbide tipped scoring knife. Circular cuts: Use a standard masonry hole saw fitted to a drill or a jig saw.

Score-and-snap the board firmly using a straight edge as a guide. Pull the board edge upwards to snap. Straight cuts: Magply is easily cut using a carbide tipped scoring knife. Circular cuts: Use a standard masonry hole saw fitted to a drill or a jig saw.

Fixing Magply Fasten Magply with adhesive, nails or screws (approximately every 200mm). Tape joints before tiling. Fixings are 15mm from edges and 50mm from corners of sheets.