Magply recovery and protection boards have been developed to meet the roofing industry needs for a cost effective, lightweight and fireproof board that will provide an inert and stable separating layer for all types of waterproofing overlay applications. Magply can also be used as a tough, durable and reusable protection layer over completed installations. 9mm Magply provides a fire-safe, lightweight environmentally friendly solution for Spandrel Panels.

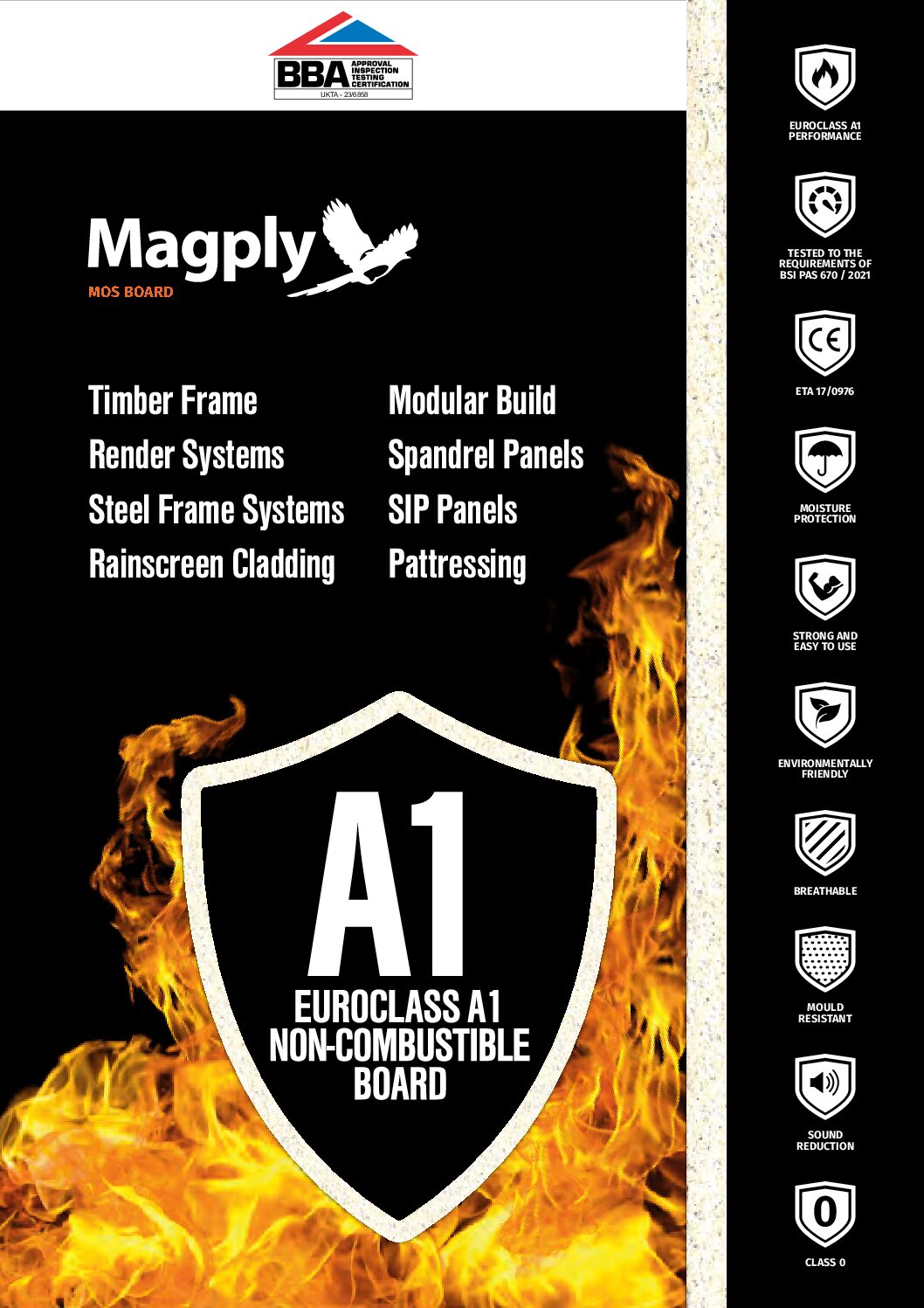

As a high performance, multi-functional board, Magply features a Magnesium Sulphate and is certified Euroclass A1 EN 13501. The boards are available in 3mm and 6mm 1200mm x 800mm to suit both lightweight and heavy traffic applications. Boards can be easily cut to fit around penetrations and at abutments – they can be either mechanically fixed or bonded into position before laying the vapour barrier.

Gallery

Magply recovery board specification

Fire Performance

Magply satisfies the performance requirements specified in Euroclass EN13501 (A1 Non-Combustible)

Thermal Performance

Thermal Resistance: 3mm 0.016 m2K/W

Thermal Resistance: 6mm 0.032 m2K/W

Board Size: 1200mm x 800mm (0.96m2)

Weight: 3mm Board 3Kg 6mm Board 6Kg

Installation

Protection Board

Where being used as a protection board the product may be loose -laid over the horizontal and vertical surfaces. Joints should be closely butted to ensure no debris gets under the boards. The board installation should be sealed to the structure at its perimeter to minimize the risk of wind uplift. It may be necessary to provide additional ballast to the completed installation to protect against wind uplift in exposed locations and on high buildings.

Recovery Board

Examine the existing roof for areas of wet insulation and/or wet or deteriorated decking. Remove and replace wet or deteriorated material as necessary. All roofs to be recovered should be evaluated for the presence of an existing vapor barrier.

Where Magply is used as a recovery board the product may be either bonded to the existing waterproofing or mechanically fixed to the structural deck. Where mechanical fixing is required, the fixing type and size should always be specified by the fixing supplier. Where the board is to be bonded to the existing waterproofing, either 95/25 bonding bitumen or a PU adhesive may be used as the bonding product.

Boards should be primed before receiving the vapour barrier.

Fixing and cutting

Magply not only cuts better, but the boards are not prone to cracking or splitting if they are installed with pressurised nail guns. Magply can be easily cut to size on site using the score and snap method. Using a pencil, mark the required size and score along the pencil line suing a utility knife and straight edge ensuring you cut through the reinforcing mesh.

Magply not only cuts better, but the boards are not prone to cracking or splitting if they are installed with pressurised nail guns. Magply can be easily cut to size on site using the score and snap method. Using a pencil, mark the required size and score along the pencil line suing a utility knife and straight edge ensuring you cut through the reinforcing mesh.