Magply is designed to accept direct render applications to form the external façades of commercial and domestic properties which utilise hybrid frames structures.

Available in 12mm, Magply offers the perfect substrate board for many render systems in external locations and is suitable for steel frame, timber frame construction and Park home & modular construction.

Magply is a high strength board manufactured using inorganic substances and reinforcement meshes which provide excellent dimensional stability.

Magply is A1 Non-combustible offering excellent fire resistance and is resistant to frost, moisture and impact and has been tested by the leading render manufacturers and at the British board of Agrément (BBA).

We recommend 12mm Magply for Render applications

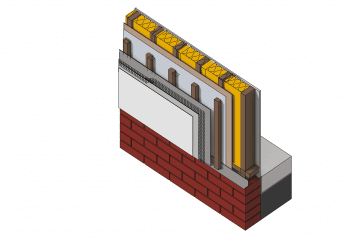

Technical Drawings

- Internal Finish

- Insulation between Timber Frame

- 9mm Magply/Manufacturers board finish

- Breather Membrane

- Vertical batten (min. 25mm)

- Magply 12mm board (render to manufacturers recommended thickness)

- Base Coat

- Exterior Finish

- Insect Mesh

Contact IPP for detailed drawings, Installation Guide, FAQ’s and further technical information. 01621 776252

Gallery

Technical Information

12mm

Width (mm): 1200

Length (mm): 800, 2400

Weight (kg.m2): 13.19

Weight per board: 13, 38

Surface m2: 0.96, 2.88

Fire Classification: Class 0 Euroclass EN13501* A1 (Non-Combustible)

Reaction to Fire: Passed BS EN 1716 Reaction to Fire* Passed

Appearance: Solid flat sheet board

Colour & Odour: White, Odourless Change of State None

Vapour Resistance: Vapour Resistance 0.31 MNs/g (EN ISO 12572*)

Melting point: Melting point: 2400°C

Vapour pressure: EN ISO 12572: 2016 = 0.31 MNs.g-1.

pH level: pH level: 7.5

Solubility: Solubility: Insoluble in Water

Acoustic: 9mm Rw 28dB 12mm Rw 29dB 20mm Rw 31dB EN ISO 717-1:2013

Important guidance notes for installer

- Minimum 25mm batten fixed at maximum 600mm centres. Fixings set at 300mm centres, guidance must be taken from the architect or engineer.

- Minimum 25mm continuous cavity behind the board top to bottom finishing 150mm from ground level and 5mm from top soffit.

- Boards should be mechanically fixed minimum 42mm for 12mm. Guidance should be taken for the architect or engineer.

- Boards should be staggered and always render on the course side of the board.

- Always screw Magply at least 15mm in from the edge of the board.

- A layer of DPC is recommended on the face of the batten behind the board.

- Air flow should be specific around windows and doors.

- Ensure the board is free from all debris and dry before applying render.

- The final installation drawing should always come from your structural engineer or architect.