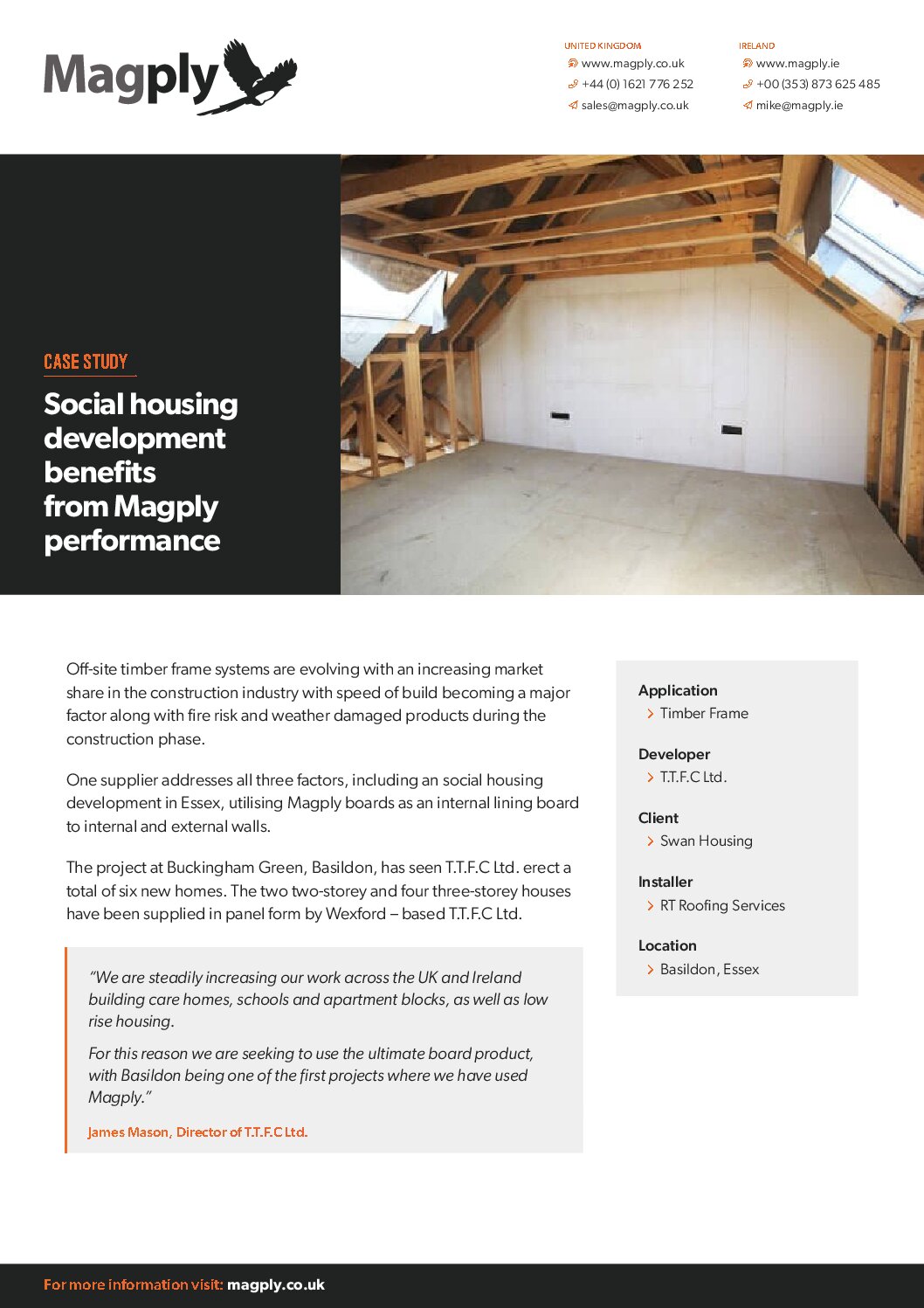

Off-site timber frame systems are evolving with an increasing market share in the construction industry with speed of build becoming a major factor along with fire risk and weather damaged products during the construction phase. One supplier addresses all three factors, including a social housing development in Essex, utilising Magply boards as an internal lining board to internal and external walls. The project at Buckingham Green, Basildon, has seen T.T.F.C Ltd. erect a total of six new homes. The two two-storey and four three-storey houses have been supplied in panel form by Wexford – based T.T.F.C Ltd.

“We are steadily increasing our work across the UK and Ireland building care homes, schools and block of flats, as well as low rise housing” says James Mason, Director of T.T.F.C Ltd. “For this reason we are seeking to use the ultimate board product, with Basildon being one of the first projects where we have used Magply.”

“Most importantly the 12mm Magply is strong enough to withstand being transported to site and the erection process without damage, while it is also very resistant to being exposed to bad weather before the building is completed. Basically for the exterior walls we will use the Magply as an interior lining and for both sides of the internal partitions or dividing walls, instead of plasterboard.”

T.T.F.C Ltd. now routinely installs 99 per cent of the Magply boards within its Wexford factory, before they are shipped to site and assembled by fully trained erection teams. They then use additional sheets of the strong and durable material to protect and complete interfaces, including within stairwells to flats and houses. This provides immediate continuity and fire resistance, while keeping the timber and insulation dry.

The site manager for Swan Housing on the Basildon project confirmed Magply’s accreditations confirming the boards’ ability to performance capabilities adding: “We have been very pleased with the quality of the timber frame units provided, while the Magply has also proved its worth. We had a very heavy downpour soon after erection work began and if the wall had been lined with conventional plasterboard they would likely have sagged – ending up on the floor. “As a high performance, multi-functional board, Magply features a formulation that provides a fire-safe and environmentally friendly alternative to conventional plywood or OSB products. Additionally, the unique production process ensures chloride content at a negligible level of around 0.03%, ensuring Magply remains dry and non-corrosive whilst enhancing both stability and long-term durability. Crucially, Magply carries internationally recognised EN Standard, UKAS accredited certification confirming 90 minutes fire integrity and insulation under test conditions and Euro class A1 non-combustibility. Furthermore, the range offers excellent racking strength, impact or pull-out resistance and all round ease of use in a variety of applications. Magply has been tested under BS 476 Part 22 for timber frame applications and parts 6&7 (Class O) surface spread of flame together with other approvals such as EN 1364-1 and EN 1365-1 for unloaded or loaded wall applications.